Bryte

- Location:

- 's Gravenzande, Nederland

- Crop:

- Tomatoes

- Surface:

- 82.500 m2

- Type of installation:

- Growlight, electrical installation

- Realized:

- 2022

Tomato nursery Bryte is taking the next step in sustainable year-round cultivation. With the installation of more than 8,000 LED modules, the company is able to guarantee year-round quality with 40% more light output and 40% less energy. This is an understandable move in the current market conditions. As a proud partner, Stolze talked to a cultivation specialist from Bryte: Erik Zwinkels.

In 2019, Bryte exchanged its SON-T lighting for a hybrid installation at the GreenBalance location in Naaldwijk. This made them the first Dutch tomato nursery with hybrid lighting. The combination of LEDs and assimilation lighting quickly proved itself; the energy savings were considerable and the LEDs provided many advantages from a cultivation point of view.

The new installation required a new growing method. For example, the cultivation strategy was adjusted and new ways were devised to grow as energy-efficiently as possible. Erik Zwinkels explains: "With the arrival of the hybrid installation, the radiant heat was halved. To keep the heat inside the greenhouse, we left the blackout screen closed as much as possible, but you don't want to block the sun all winter, of course. That's why we're opting for a second screen installation this winter: an energy screen."

More flexible, energy-efficient, and sustainable growing process

This summer, the progressive company was ready for the next step. Bryte had expected to grow hybrids for at least five years before switching completely to LEDs; this expectation was overtaken by the current conditions in the energy market. "With our full LED tomato nursery, we're going to save 40% in energy and we've increased the light level by 40%. That gives us more flexibility with the high energy prices and enables us to continue producing year round." This is an understandable choice and a logical step according to the grower. "Year-round cultivation is absolutely possible in the Netherlands. As entrepreneurs, we stand behind this promise and dare to invest. This is the only way to guarantee our customers year-round quality."

Growing together

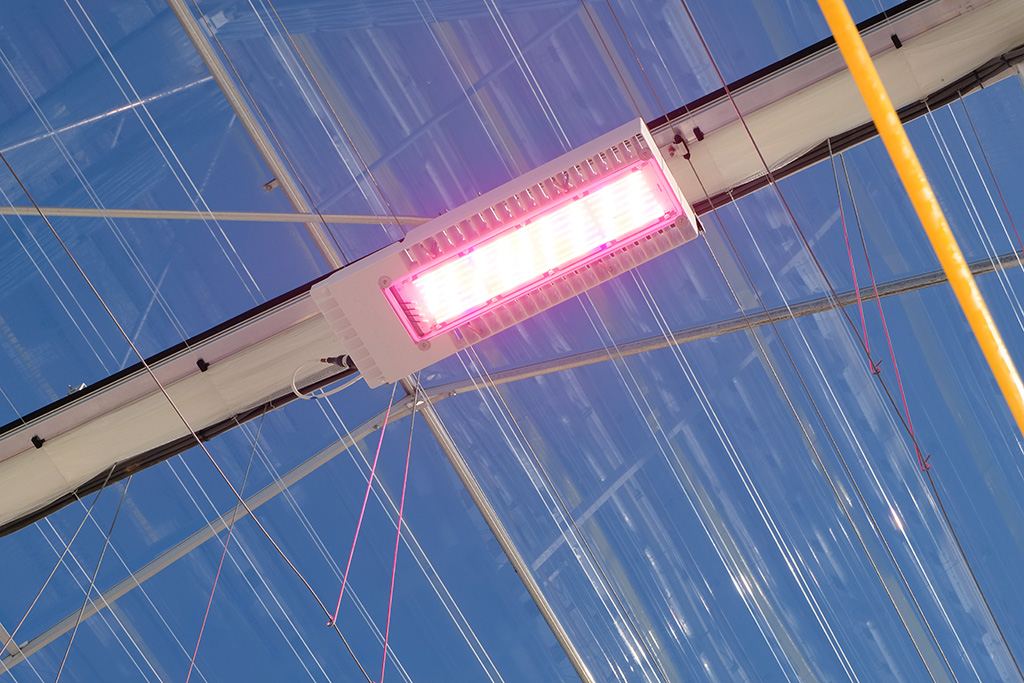

Together with the specialists from Stolze and Signify, the company opted for the Philips GreenPower LED toplighting compact. Bryte chose this module because of its optimal light level and good working conditions; thanks to the 6% green, 6% blue, and 88% deep red color combination, it is even possible to harvest. Stolze's input offers the tomato nursery a lot of added value, says Erik: "We've been working with Stolze for almost 20 years. They know our company inside and out, have a lot of knowledge and extensive expertise and, therefore, they give us sound advice."

Stolze integrated the entire LED installation and also took care of the disassembly of the existing modules. "Once again, Stolze fulfilled all of its promises, and we're extremely satisfied with this lasting relationship!". The company expects the step from hybrid to full LED to be greater than from SON-T to hybrid. Erik: "Fortunately, Stolze's specialists are always there for us with excellent service and advice!".

Back to summary